The Pros and Cons of Cerakote and Anodizing finishes explored.

How did we get to Cerakote?

Just as the materials and processes used to manufacture firearms over the years have evolved, so have coating technologies.

In the early 20th century, when everything was made out of steel, parkerization (phosphating) was the name of the game. It provided a robust and chemically-resistant finish (due to its ability to hold oil) but only worked with steel because it is a chemical process that interacted with the iron content of the steel. In the latter half of the 20th century, with the adoption of aluminum and polymers as construction materials for firearms, anodizing grew in popularity, creating the “black rifle” look known so well worldwide. This is still the industry-standard for firearm coating. Now, in the 21st century, with the proliferation of observation devices, both in the visible light and near infra-red (NIR) we need all those same properties of the previous coating technologies plus the ability to camouflage into the environment…

Enter Cerakote.

What is Cerakote?

Cerakote is a high-performance, ceramic-based coating that can be applied to a variety of materials, including metals, plastics, polymers and wood. It is engineered to provide a durable, long-lasting finish that is both protective and aesthetically pleasing. The coating is made from a proprietary blend of ceramic particles held in place by a polymer matrix which creates a unique surface finish with exceptional hardness and corrosion resistance. These ceramic particles provide hardness and abrasion resistance, while the polymer binder contributes to flexibility and the adhesion of the coating to the substrate. The exact composition depends on the variety of cerakote and its intended application.

- Ceramic Particles: These are typically made from materials like aluminum oxide, titanium dioxide and silicon dioxide, which are known for their hardness and resistance to wear.

- Polymers: The polymer component usually consists of various thermosetting resins that cure to form a tough, durable matrix. These resins are selected for their chemical resistance and ability to bond effectively with the ceramic particles.

- Pigments: Cerakote is available in a wide range of colors and the pigments used are chosen for their stability and resistance to fading under UV exposure.

- Additives: Various other additives may be included to enhance specific properties, such as UV resistance, corrosion resistance, or lubricity.

In short, Cerakote is kind of like an ultra-fancy spray paint with some serious staying power.

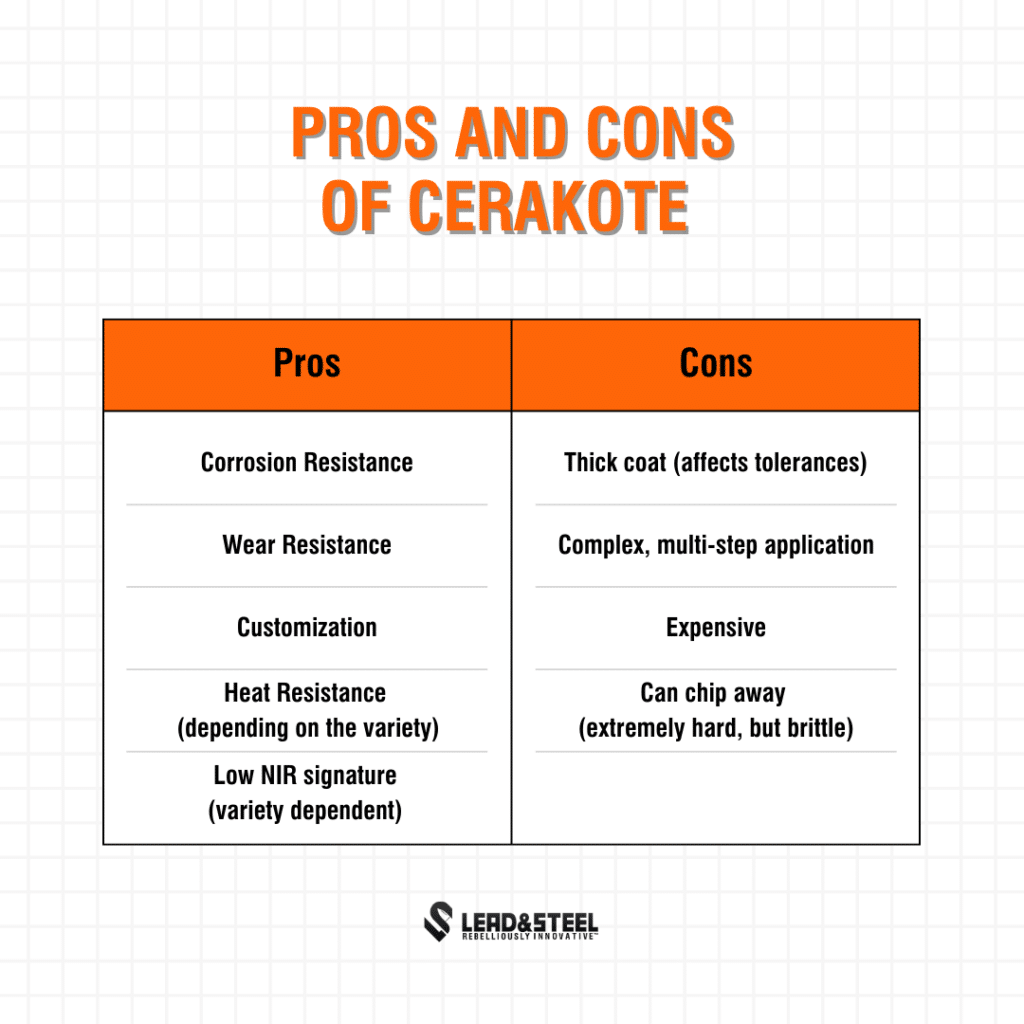

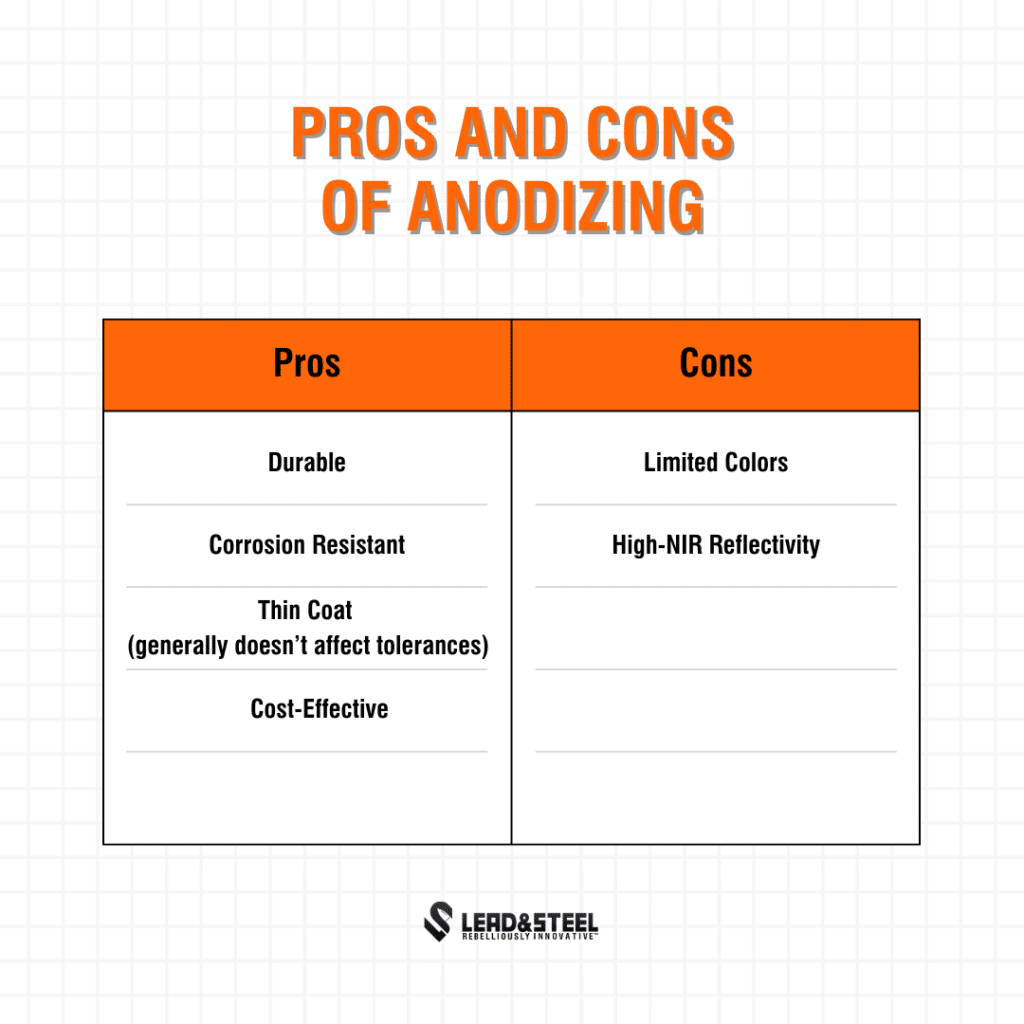

Benefits and Drawbacks of Cerakote VS Anodized Parts

Anodized Parts:

Anodizing, on the other hand, is an electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant, anodic oxide finish. This process involves immersing the aluminum part in an acid electrolyte bath and passing an electric current through it, which causes the surface to oxidize.

The Military Standard for Cerakote

Camouflage has been a part of warfare for thousands of years, but with the global propagation of I2 night vision in the 21st century, the modern combatant needs to consider camouflage in BOTH the visible light spectrum and the IR spectrum. Also thermal, but that’s not the subject “du jour”.

The United States military recognized this fact and issued a standard for NIR reflectivity by which equipment must abide: MIL-DTL-44436. Cerakote developed their Gen II Coating specifically to fulfill this requirement.

And now a quick physics/biology lesson: Your eyeballs are energy sensors. They collect energy and can translate some of that energy, from the visible light part of the electro magnetic spectrum, into data which your brain can interpret as the world around you.

All the “stuff” you see with your eyeballs is light that is bouncing off of that “stuff” and entering your photoreceptors (eyeballs). When light hits different materials, it reacts differently. For example, a cloth that you or I might perceive as red, reflects the red part of the visible light spectrum, while absorbing the yellow and blue, entirely. (I won’t go any deeper into color science on this one).

This same phenomenon happens in different parts of the magnetic spectrum that your eyeball can only pick up with assistance. Enter I2 night vision. Night vision tubes take photons (light) before they get to your eye, and duplicate them, so there are more photons going into your eye than went into the Night Vision Device. In this process, it collects photons that the eyeball can normally perceive and some it can’t (Near Infra-Red, or NIR) and then it makes them all either green or white.

This means, with night vision, you can actually see NIR.

There are a lot of man made items that reflect IR energy in odd ways. For example, a black anodized firearm sucks in all those IR photons, leaving a very obvious and identifiable dark shape. On the other hand, a firearm coated with gen II cerakote might reflect IR in a similar way that leaves, grass, or other organic matter would.

So what’s the deal with all the Cerakote talk? For the past five months, we’ve been immersed in testing, building, and evaluating different finishes and camo patterns for our lineup. While anodized products will always have a place, and we might still rattle-can a few personal projects, we can’t ignore the incredible range of options Cerakote offers. It’s been on our minds, and we’re excited to share it with you.

In conclusion, Cerakote is in many ways becoming the standard for firearms coating, but will never fully replace anodizing. We’ve teamed up with Weaponworks for a limited run of NIR-rated camo Cerakote rifles, featuring the fan-favorite camos from our March Madness bracket. Whether you prefer the timeless appeal of our classic anodized finish or the cutting-edge camo Cerakote, find the All-Rounder Carbine that fits your style and needs.